Digitalisation has the power to completely change the way the chemical industry, and society in general, works, communicates, innovates, produces and consumes. It can bring unprecedented transparency to value chains. Cefic’s recent Mid-Century Vision document ‘Molecule Managers’ predicts that data will have replaced oil as the most valuable commodity by 2050.

.jpg)

The possibilities for digital transformation

Digital in its many flavours, from data mining to artificial intelligence (AI), predictive maintenance and data-based process management, can transform the chemical industry. It can enable critical societal change such as the circular economy by, for example, implementing blockchain and other distributed ledger technologies to introduce transparency and enable the tracking of molecules through the economy from production to processing and use to recycling and reuse.

“Digitalisation will be a source and driver of transformational change across the chemical industry, with an emphasis on safety and operational excellence,” says Dr. Martin Winter, Innovation Manager at Cefic who is currently working on the new SusChem Strategic Innovation and Research Agenda (SIRA) that will feature digital innovation. The new SIRA will elaborate a range of detailed research and innovation priorities in enabling digital technologies for the chemical sector and should be published in November.

“To strengthen its global competitiveness, the European chemical industry must leverage the benefits that key digital enabling technologies and advanced data management toolboxes can offer today,” argues Winter. “The change will happen horizontally and cover the entire product life cycle, including every step of sourcing, production and sales processes, and across entire value chains.”

Digital technologies will contribute to integrated production management of chemicals that optimises all aspects of sustainability from asset-data to production scheduling and organising optimal flows of materials and energy.

Digitalisation can also disrupt value chains by empowering local, more specialised value chains driven by remote and flexible production sites: themselves enabled by powerful digital process analytical and control technologies. The chemical industry will develop new, data-based business models and supply chain management, and implement a more rational design for rapid upscaling of production processes. “Simultaneously, products will also increasingly incorporate digital service components, enabled by an abundant flow of data, to strengthen the competitiveness of the sector’s entire offer,” says Winter.

Technologies already in place

Many digital technologies are already established within the industry, such as advanced data generation, processing and analysis, AI and supercomputing for predictive maintenance, process control, and development of digital twins: virtual comprehensive computer models of whole processes and product lifecycles. As these technologies further mature, they will be scaled up, mainstreamed across the entire value chains and fully integrated into new business models.

What the industry should focus on

To integrate the advantages of digitalisation into the industry will require an appropriately trained workforce. The recent SPIRE Position paper on AI quotes an estimate that a typical €10 billion turnover, 15000 employee chemical company might need between 500 to 1500 full-time employees with a comprehensive digital skill set (for example data-scientists or IT engineers). These skills are currently in short supply and a major educational effort will be required to ensure Europe has the right workforce to enable its digital future.

“Of course, in this new era of immediate and ubiquitous digital data exchange and taking into account the huge value generated through data-ownership, the chemical industry must also be an important stakeholder in initiatives on industrial cybersecurity,” highlights Winter. “Advanced security solutions need to be developed to prevent misuse of stored data and protect plant control and wireless systems or cloud-based data from any form of interference.”

A path towards sustainable solutions

Applied digital technologies present a major opportunity for the chemical industry to contribute to long-term European policy goals. Digitalisation will have huge social and economic impact by making processing plants and operations more resource and energy efficient. It can reinforce safety and risk management, secure product quality, and contribute to significant reductions in greenhouse gas emissions. Digital is essential to orchestrate the path towards a sustainable carbon-neutral, circular economy including new digitally enabled supply chain-structures such as large-scale industrial symbiosis platforms.

Sustainability will not come at the expense of choice, quality or service. Digital technologies applied to product and process development will speed-up innovation, enabling a more efficient “idea-to-market” process that results in faster industry responses to market and customer demands.

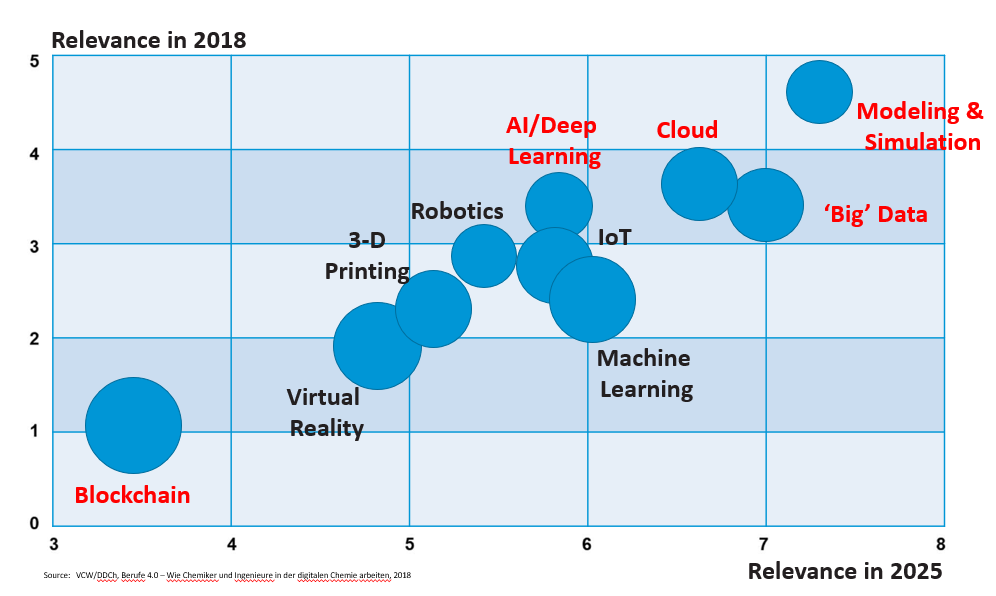

Expected development of disruptive digital technologies in the chemical industry by 2018 -2025

Look out for future Digital Chemicals articles focusing on the potential impact of Artificial Intelligence (AI) and Blockchain and related technologies on the sector.